Sewertronics

Systems to renovate mainlines, laterals, Manholes, in-house drains and sectional repairs in sewer pipes.

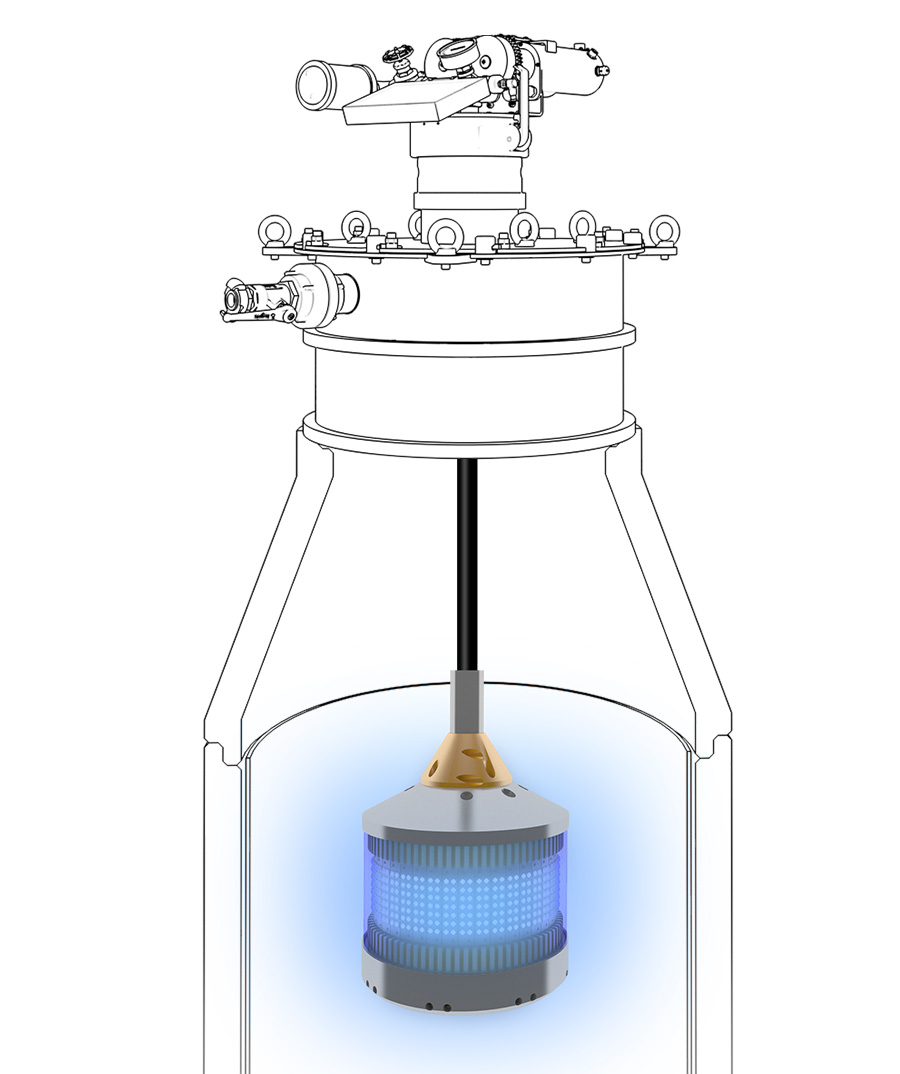

SpeedyLight+

Fast Light Curing Technology

Size range: 2″ – 24″

The SpeedyLight+ LED curing system is a game changer in the sewer renovation market. Its revolutionary LED technology allows contractors to optimise their operations by increasing working efficiency at the job site up to six times. It is designed to cure felt liners, invertible glass-fibre liners and fibre-glass pull-in liners.

Compatible with felt liners and GRP UV liners. It is also compatible with our SpectraDive curing head for manhole rehabilitation. SpeedyLight+ can also do point repair with our family of LED packers.

SpeedyLight VX

Efficient Curing for Vertical and In-House Pipes

Size range: 6″ – 24″

SpeedyLight VX LED is designed for vertical and in-house no-dig rehabilitation. This system, paired with resins that deliver no shrinkage in the final cured liners, drastically reduces curing times, eliminating downtimes and safety hazards associated with ambient curing resins.

LEDRig

Efficient UV Glass-Fibre Liner Curing

Size range: 6″ – 24″

LEDRig devices are designed for curing glass fibre-reinforced polymer (GFRP) liners in sewer rehabilitation and manholes. Our patented cooling technology enhances LED efficiency, reducing both curing time and energy consumption compared to traditional UV lamps.

QuickPatch LED

Efficient Spot Repair with QuickPatch LED

Size range: 3″ – 18″

Sewertronics’ QuickPatch LED offers a shadowless solution for spot repairs, curing prepregs from 3″ to 18″. With high-power LED technology, it ensures complete and even curing in just 3-5 minutes.

SpectraDive

Unparalleled Versatility and Efficiency to Manhole Rehabilitation

The Spectra Dive series, developed by Sewertronics in collaboration with Brandenburger Vertical 2.5 liner, introduces advanced manhole rehabilitation solutions.

Available in two versions—Dive-S1800 compatible with SpeedyLight+ and Dive-L2400 compatible with LEDRig—these units enhance the versatility and efficiency of existing UV curing systems without requiring updates or power modifications.

Minicam Trenchless

Email: sales@minicaminc.com

Phone: (734) 452 7068

Minicam Inc HQ & Midwest Service Center

Address

12600 Newburgh Road

Livonia

Michigan

48150

Email: info@minicaminc.com

Phone: (734) 744 5557

Massachusetts Service Center

Address

1 Industrial Way, Unit 2

Tyngsborough

Massachusetts

01879

Email: newengland@minicaminc.com

Phone: (978) 643 0397

Florida Service Center

Address

2332 Old Combee Rd

Lakeland

Florida

33805

Email: florida@minicaminc.com

Phone: (863) 345 7303

California Service Center

Address

703 W. Anaheim Street

Long Beach

California

90813

Email: california@minicaminc.com

Phone: (562) 620 3574